Automation hardware

Table of contents

Introduction

Ongoing WMS is hardware independent and Ongoing WMS does not distribute nor sell any automation hardware. Automation hardware is integrated with the WMS through our standardized automation API. This means that you can choose any hardware supplier, and either develop the integration yourself, or let the hardware supplier or an external IT-consultant build the integration. There is a description on how to use the Automation API here.

There are many reasons to automate warehouse processes, such as increased speed, better storage utilization, fewer picking errors or better ergonomics. Depending on what you want to achieve, you might want to integrate different types of equipment.

Level of warehouse automation

When speaking about automation in warehouses, often a high level of automation is considered. However, even using scanning is a type of automation. Warehouse automation is often divided into two main areas: decision making (e.g., what to pick) and movement of goods. No automation means that a human is handling the complete process, both decision making and moving goods, whereas the highest level of automation would not involve any human interaction at all. Implementing a WMS increases the level of automation for decision making, as does using scanning, but the automation of moving goods has not changed. In this article we will look at solutions for higher level of automation, both in terms of movement of goods and decision making. You find more information about using scanning here.

Automation hardware

Bellow we have listed some examples of automation hardware.

Conveyor belt

A conveyor belt is used to transport objects from one place to another, hence increasing the automation of movement of goods. The conveyor belts may have the ability to move objects to different places depending on the object itself and would then also increase the automation in decision making. For instance, in a warehouse you may wish to have the conveyor belt move all packages going to Sweden to one location, while all packages going to Norway should be moved to another location altogether.

Implementation example

When integrating a conveyor belt, it is possible to let the belt itself perform moves from one location to another in Ongoing WMS.

Example of hardware used by our customers:

Vertical storage lift

A vertical storage lift is a machine consisting of several internal locations and some mechanism which can automatically transfer goods between these internal locations and some designated input/output areas. Vertical storage lifts are for example used to increase the utilization of the warehouse, reduce the picking time and increase the accuracy.

Implementation example

When integrating a vertical storage lift, the storage lift will get information from Ongoing WMS about what should be picked and then the lift's execution system will move or pick the articles from Ongoing WMS through the API. Depending on the solution, the lift might optimize the picking sequence to minimize the picking time, or sole act to increase storage utilization, but the picking sequence is not optimized.

Example of hardware used by our customers:

-

Kardex Remstar Shuttle - read more about a customer case with Kardex here.

-

Weland Solutions' vertical storage lifts through Compact Store

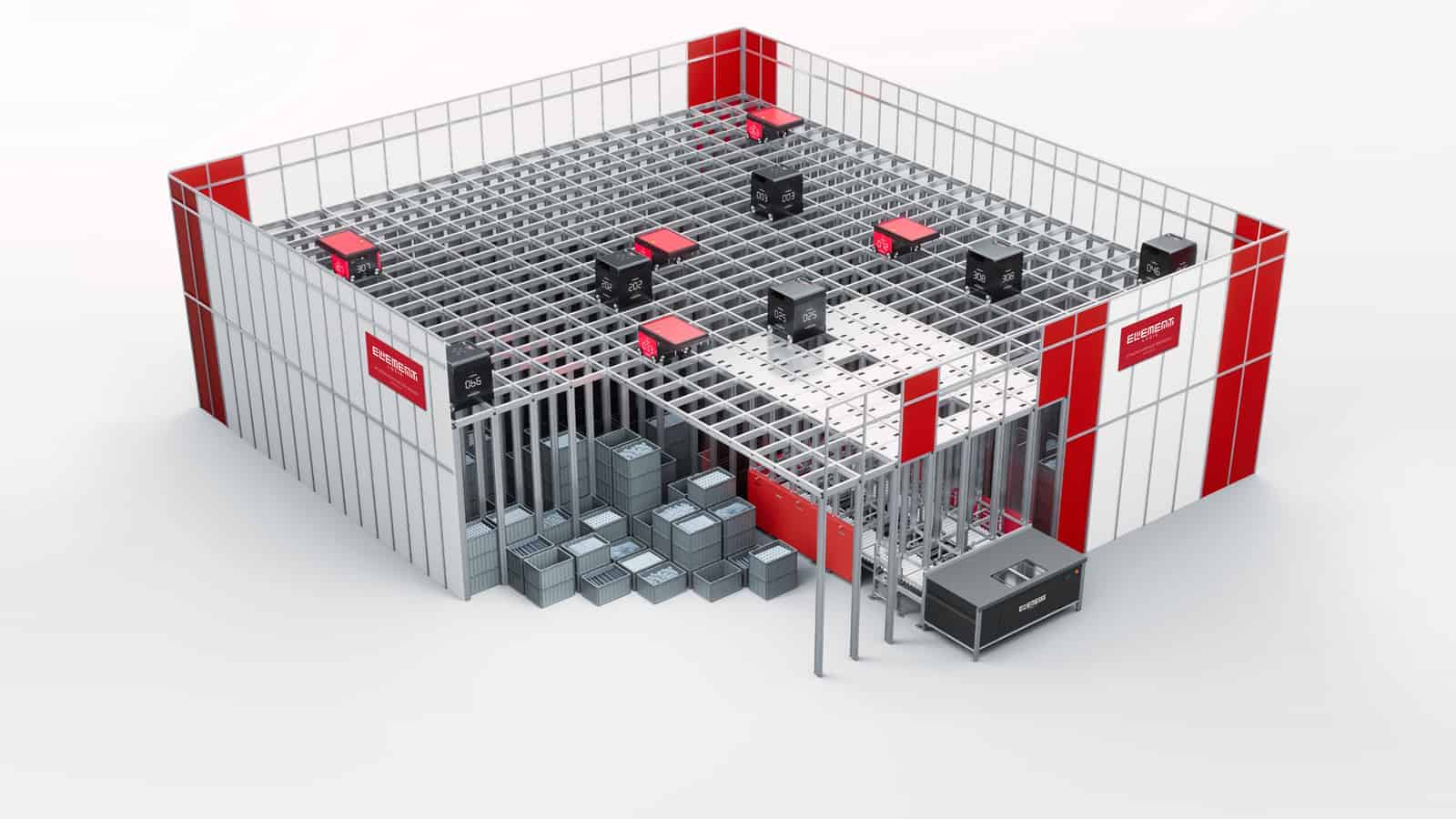

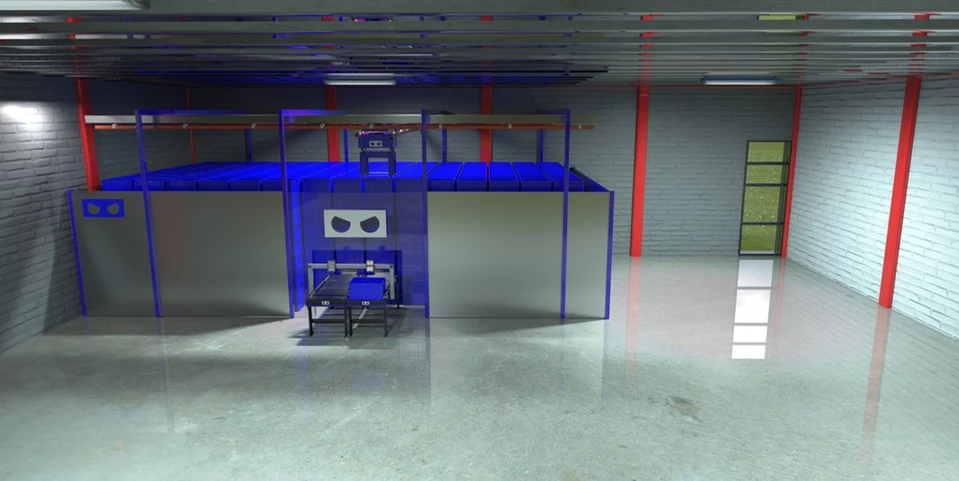

Automated Storage and Retrieval System (ASRS)

ASRS can make warehouses both more space efficient and increase the picking efficiency.

Example of hardware used by our customers:

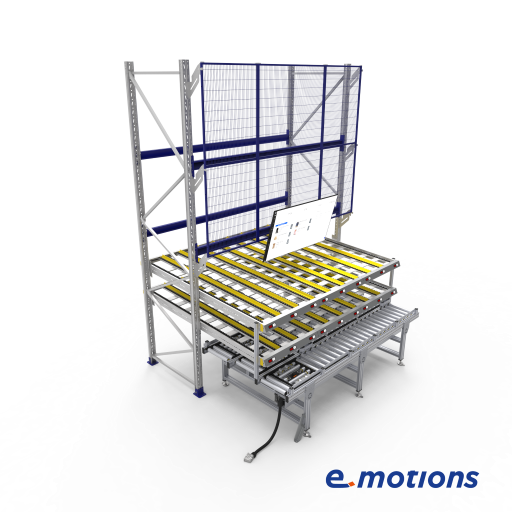

Pick-to-light

In a pick-to-light setup (also known as pick-by-light), the locations which the warehouse operator is supposed to pick from are indicated by lights. The warehouse operator selects an order to pick, and each bin which he is supposed to pick from lights up. As the operator picks items, he confirms each pick by pressing a button.

Usually only the most common articles are stored in the pick-to-light zone. If an order contains other articles, the warehouse operator passes the order on to someone who works in the other zone.

Example of hardware used by our customers:

Automated Packaging Systems

Automated Packaging Systems can help warehouses automate the last part of order expediting process. Putting items into the packaging and closing the package. It can also help minimizing air in shipments by creating a package specifically designed for the items. Lastly, it might also help to automatically print and label the package for shipping.

The Automated Packaging System needs to communicate with Ongoing WMS for identifying which order it is currently working on, marking it is packed and fetching labels for the order.

Example of hardware used by our customers

Dimensions, Weight and Scanning

An automation for dimensioning, weighing and scanning items can help you get better traceability in the warehouse as well as provide exact measurements for your shipments. The latter can help save on shipment costs. A DWS is usually combined with a conveyor which transports the package through the DWS. The DWS needs to communicate with the WMS to transfer the right dimensions.

Example of hardware used by our customers