Integration with shipping platforms

Table of contents

Introduction

To ship products to customers, most warehouses need to either:

- Book transport services from outside carriers, or

- Manage their own fleet of transport vehicles.

The transports are generally managed in a separate system. To get an efficient and error-free workflow, you want to eliminate as many manual steps as possible. A good solution should:

- Involve as little manual data-entry as possible.

- Be fully automatic when transferring data.

Workflow

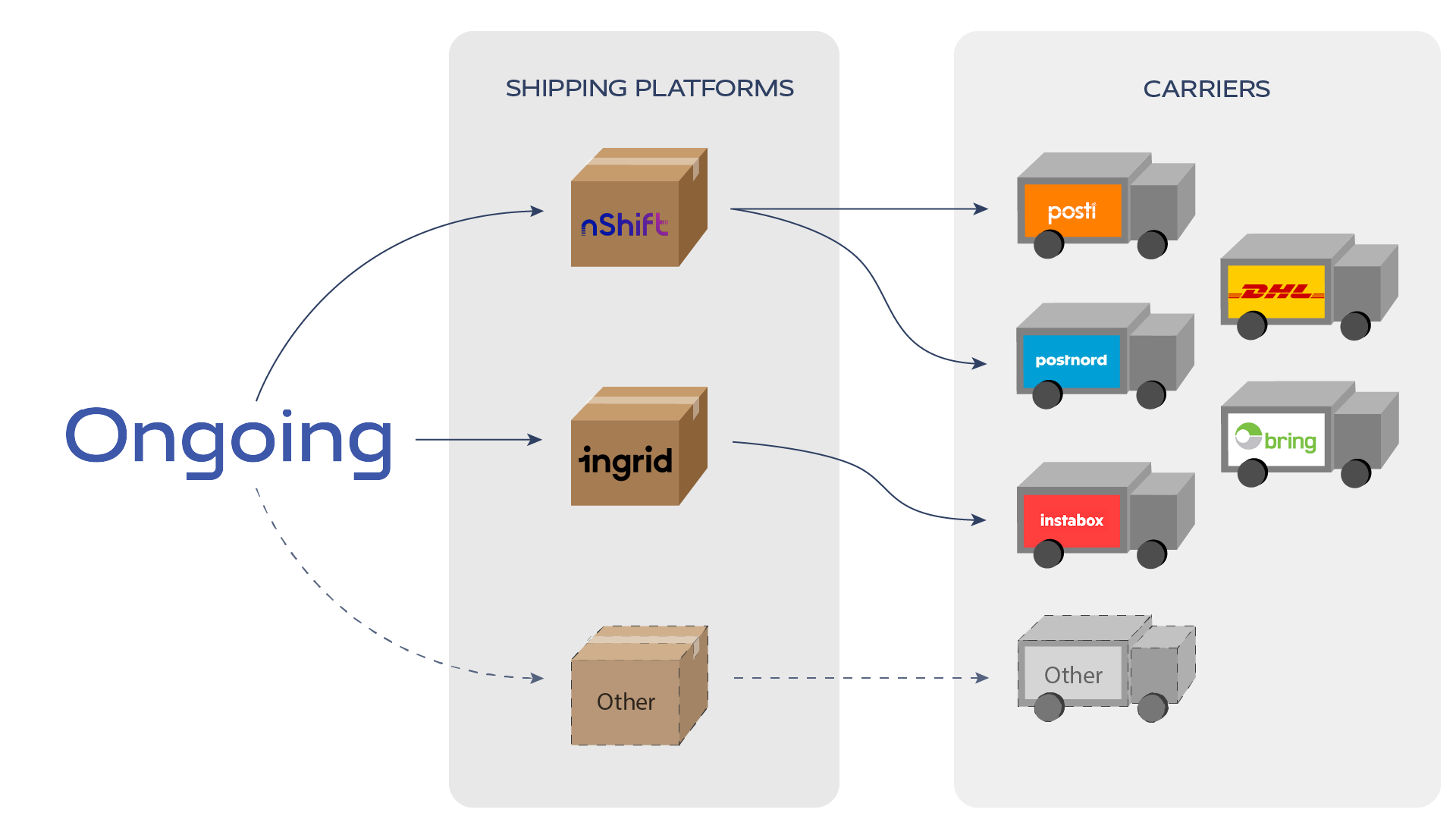

A popular solution in the Northern European market is to use a shipping platform. These are software platforms for shipping which sit between the party which wants to ship something (such as a warehouse) and the actual carriers. The shipping platform presents a uniform view of all carriers, which means that if you ever want to switch carriers, no additional software development will be required.

There are also transport and fleet management systems which are like shipping platforms. In this article we use shipping platform for both.

When using a shipping platform together with Ongoing WMS, there are three kinds of parties involved:

- The warehouse.

- The shipping platform.

- The carriers.

Schematically, a workflow involving an integration with a shipping platform looks like this:

This is what the workflow looks like in more detail:

- An order is placed in Ongoing WMS. This can either be done manually, or the order can be sent to Ongoing WMS via an integration with an ERP or web shop.

- The warehouse operator picks and packs the order.

- The warehouse operator checks that the correct carrier has been selected for the order, and then fills in the remaining information which is required for booking transport (e.g. number of packages or pallets).

- The warehouse operator can now use the integration to send all the required data over to the shipping platform, with the click of a button.

- The shipping platform sends the information to the carrier and responds to Ongoing WMS with a shipping label and tracking information.

Which shipping platform?

The most important consideration when choosing a shipping platform is that it needs to support the carriers which you intend to use.

Ongoing WMS currently provides integrations available with the following shipping platforms:

- Cargoflux

- EasyPost

- Frigoscandia TA-connect

- Homerunner

- Huxloe

- Ingrid

- Intersoft Sapient

- LetMeShip

- Link Logistics

- Logistra Cargonizer

- LogiSystems KuljetusVelho

- Logtrade

- NoParcels

- nShift Delivery (formerly Unifaun Online)

- nShift Ship (formerly Consignor and DeliveryHub)

- Opter (formerly Fleet101 K2)

- pinDeliver

- Posti SmartShip

- Profrakt

- Qapla

- Sendcloud

- Sendify

- shipcloud

- Shipit

- Shipmondo

- ShippyPro

- Shyplite

- Smart Send

- Transsmart

- Unifaun Web-TA

- VeniShip by Venipak

- Versafleet

- Webshipper

- Webshipper Delivery integration

- Webshipper Order integration

- Zendera

- Zhipster

The following companies have developed their own integrations from their shipping platform to Ongoing WMS:

Next step

If you wish to integrate with a shipping platform where the integration is provided by Ongoing, please see our guide on how to add an integration.