Introduction to scanning

Table of contents

- Introduction

- Hand-held device requirements

- Processes which can be handled with hand-held units

- Scanning types

- Location labels

- General adjustment possibilities

- Languages

Introduction

We offer a set of standard scanning flows developed to cover the most common requirements when using hand-held units in a warehouse. The scanning flows are easy to adjust to specific customer needs. Using a standard scanning is cost effective, since it requires less development time, and is fast to set up. Using standard scanning is a good way to create a standardized way of working with all your goods owners and to streamline the work flow.

Hand-held unit requirements

To be able to use scanning in Ongoing, the hand-held unit must support the following:

- Internet connection, either by 3G(+) or WLAN.

- Web browser.

- Barcode compatibility i.e. the hand-held unit must support the type of barcodes that you want to use.

- Good screen resolution is not a requirement, but is recommended.

We provide a guide for selecting scanning hardware.

For further information about what hand-held units are most suitable for your needs, contact your hand-held unit supplier. Note that you can use any device fulfilling the requirements above, e.g. hand scanners, mobile phones or tablets with connected barcode scanners.

Processes which can be handled with hand-held units

Scanning types

Our standard scanning flows are divided into three main groups, each making different trade-offs for efficiency and traceability.

- Article number based - This is the most common type of scanning. The articles are identified only by their article number. This means that you can't differentiate between two items with the same article number.

- Item based - This type of scanning differentiates between articles with the same article number by using serial numbers. The serial numbers are either already assigned to the items when they arrive at the warehouse for the inbound process, or you generate your own serial numbers and labels. An item based process increases the traceability by enabling you to trace a specific item to an order or inorder.

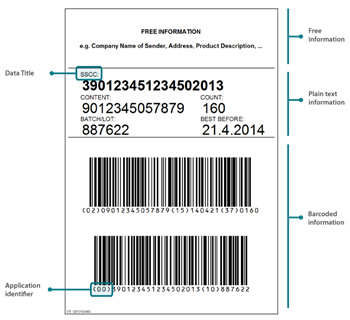

- GS1/SSCC - GS1 barcodes, sometimes referred to as SSCC barcodes, are barcodes following a specific global standard. The barcodes typically contain more information, such as batch number, expiry date and number of items.

Location labels

In most scanning processes, it is generally desirably to have a step where the operator must scan a location label. This confirms that the operator is physically present at the correct location. For instance, when receiving goods into the warehouse, an operator might follow this procedure:

- Scan article number.

- Input number of items.

- Scan location label.

- Result: goods are received into the location.

If your locations are not already marked with barcodes, it is possible for Ongoing to generate location labels.

General adjustment possibilities

-

Barcode prefix

If you have already labeled your locations differently than they are named in Ongoing we can add setting for handling any prefixes. The same holds for pre- or suffix on article numbers or any other code you are scanning. -

Messages / terminology

If your terminology is different than ours, we can replace ours to match yours. E.g. if you want to use "lot number" instead of "batch number". -

Article identification

Generally, the barcode contains the article's EAN, which is stored under the field "barcode" in Ongoing. It is possible to identify the product on other fields in Ongoing if required. It is also possible to select the articles in a drop down list instead of scanning e.g. when the articles are missing barcodes. -

User interface

The user interface is adaptable to fit your hand set unit, e.g. making text or buttons smaller or larger.

We recommend that you to start with a basic standard scanning and adjust it when you have tried the scanning for a while. To keep down the developing time, try to find a scanning flow suitable for as many of your customers as possible. Our experience is that it often is more convenient to have fewer standard scanning flows, than specialized flows for each goods owner.

Languages

At the moment, the standard scanning flows are available in Swedish, English, Danish, Norwegian and Finnish. The language is set for each user, so you can use the same scanning flow in more than one language. Contact Ongoing if you want to use the scanning in any other language.