Batch pick scanning in one bin

Table of contents

Introduction

If there are several single item orders with the same item ordered it is faster to pick all of them at the same time than picking them one by one. Since the orders are identical they don't need to be separated into different bins on a picking cart. Then the picking opition "Batch picking in one bin" is a good choice.

The standard work flow is to first prepare the orders to be picked in the order list in the system. The items which are to be picked are tied ("allocated") to the orders. After that, the orders can be processed in the hand-held unit. Whenever you scan an article, it is removed from stock. Progress can be easily monitored from the system. When all goods have been scanned, the order statuses are updated.

- By pressing "Clear" at any time during scanning of an article you can clear all scanned information for the current article.

- By pressing "Cancel" any time during the scanning you can select a new order to work with.

- By pressing "Skip" you can skip a suggested article to process. Skipped articles will be placed at the back of the line of suggested articles.

- By pressing the button "Close" at any time during the scanning you can update all order to status "Picked" and set the pick order status to "Executed".

- When the order is closed it will get the status "Picked".

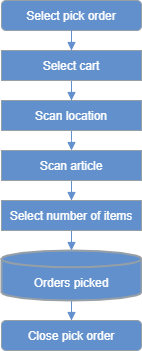

Flow chart

As can be seen in the flow chart below, the work flow is quite straight forward when doing batch picking in one bin.