Batch pick scanning

Table of contents

Introduction

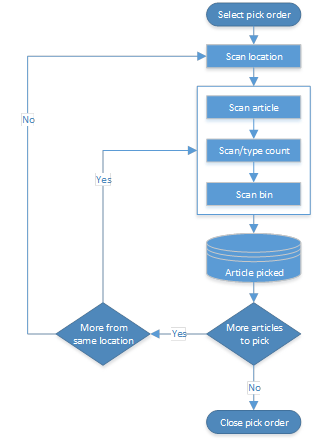

The purpose of the batch pick scanning (also known as "pick order scanning" and "picking cart scanning") is to prepare orders for shipping. The difference between a batch pick scanning flow and a single order picking scanning flow, is that in the batch pick scanning one prepares multiple orders at the same time. This requires some sort of picking cart with multiple labeled bins.

The standard work flow is to first prepare the orders to be picked in the order list in the system. The items which are to be picked are tied ("allocated") to the orders. Each order is also assigned a specific bin in the picking cart. After that, the orders can be processed in the hand-held unit. Whenever you scan an article, it is removed from stock. Progress can be easily monitored from the system. When all goods have been scanned, the order statuses are updated.

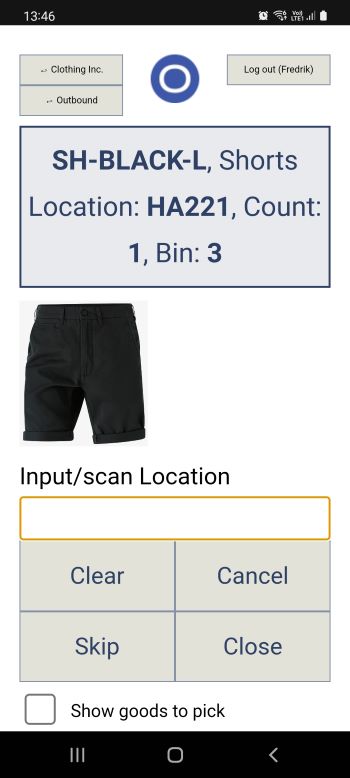

The following information can be displayed in the hand-held unit:

- A table containing the articles to pick.

- A table containing the articles which have already been picked.

- Customer information (name, address, way of delivery, and so on).

Video

We have prepared a video about batch picking with scanner in Ongoing WMS.

Settings

-

Batch type

Specify whether the scanned batch should be used to set batch or filter batch if batch numbers are used. -

Serial type

Specify whether the scanned serial number should be used to set or filter serial number if serial numbers are used. -

Allow serial duplicates

Specify whether the scanning should allow to set scanned serial number if scanned serial number already exists on another article on the order. -

Default number of items

Specify a default count to use if it is desired to skip scanning of count. -

Keep location after pick

Specify if scanned location should be saved if more items from same location should be picked or if the location is needed to be scanned for each item to pick. -

Keep article after pick

Specify if the picked article should be saved if more items from the same article should be picked or if the article is needed to be scanned for each item to pick. -

Show article dropdown list

Specify if an article drop down list should be visible to be able to choose article in the list to select the next article to scan.

Article number based scanning

- By pressing "Clear" at any time during scanning of an article you can clear all scanned information for the current article.

- By pressing "Cancel" any time during the scanning you can select a new order to work with.

- By pressing "Skip" you can skip a suggested article to process. Skipped articles will be placed at the back of the line of suggested articles.

- By pressing the button "Close" at any time during the scanning you can update all order to status "Picked" and set the pick order status to "Executed".

- When the order is closed it will get the status "Picked".

Batch picking without a scanner

The scanning module can also be used without a scanner. If you don't have access to a scanner or if the articles you handle don't have barcodes you can still use the scanning module in Ongoing WMS as a "digital pick list". The list will guide you to the right location and tell you what article to pick and in what bin on the picking cart to put it. Instead of scanning the article, warehouse location and bin on the picking cart, you simply confirm on your handheld device that you have picked the article and put the in the right bin. Below is a video that demonstrates how this works.