Inbound scanning

Table of contents

- Introduction

- Video

- Settings common to all inbound scanning flows

- Article number-based scanning

- Item-based scanning

- GS1/SSCC scanning

Introduction

The purpose of an inbound scanning is to receive goods into the WMS using a hand-held-unit. There are three main types of scanning, each described below using flowcharts.

When working in the inbound scanning, the user generally has these options available:

- By pressing "Clear" at any time during the scanning you can clear all scanned information for the current article.

- By pressing "Cancel" at any time during the scanning you will cancel the current scanning and select a new purchase order. The goods which have already been received will not be removed.

- When you close a purchase order, its status will be changed. If the received number of items equals the advised number of items, the status will be "Received". Otherwise, the status will be "Deflection".

Video

We have prepared a video about inbound scanning in Ongoing WMS.

Settings common to all inbound scanning flows

-

Use purchase orders

Before the inbound process starts, the expected number of items to be received can be entered on a purchase order. The scanning process can either work with these purchase orders, or not.

Default: Use purchase order. -

Purchase order statuses

We use purchase order statuses to determine whether a purchase order should be visible in the scanner.

Default: Purchase orders with statuses "Arrival space" or "Inbound" are visible in the scanner.

-

Show purchase order lines

Purchase order lines can be shown by default or when checking a check box.

Default: Shown when checking a check box.

-

Select purchase order line

If an article does not have a barcode, you can manually choose what purchase order line to process in a dropdown list.

Default: Depends on which standard scanning you are using.

-

Unique serial numbers

When using item-based inbound scanning, you can choose whether to accept duplicate serial numbers.

Default: do not accept duplicate serial numbers.

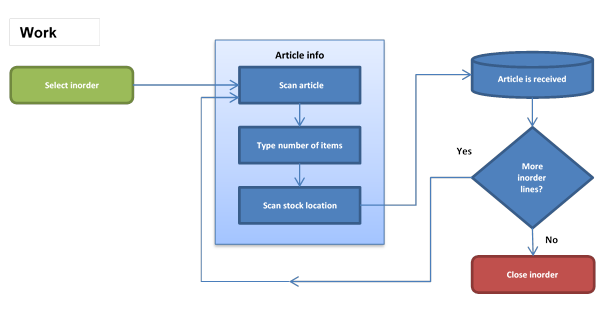

Article number-based scanning

This is the most common type of scanning. The articles are identified only by their article number. This means that you can't differentiate between two items with the same article number.

Settings

Article information

In the flow chart above we scan (or type) the articles' barcode, number of items and stock location. It is possible to scan/type the following information:

- Article

- Number of items

- Stock location

- Batch

- Serial number

- Weight

The order information scanned is adjustable.

Default stock location

You can select a stock location to receive all goods to, e.g. if you have an arrival space and want to move to goods to other locations later. The step of setting location can then be removed.

Default number of items

In the same way as for default location, a default number of items can be selected. The scanning flow will then not contain the step for adding number of items. This is useful if you are always scanning one item at the time.

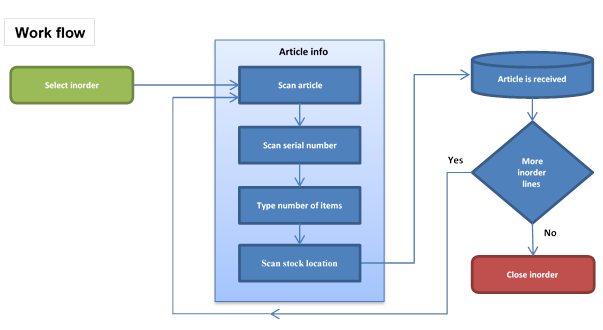

Item-based scanning

This type of scanning differentiates between articles with the same article number by using serial numbers. The serial numbers are either already assigned to the items when they arrive at the warehouse for the inbound process, or you generate your own serial numbers and labels. An item-based process increases the traceability by enabling you to trace a specific item to an order or purchase order.

Settings

Same as for article-based scanning.

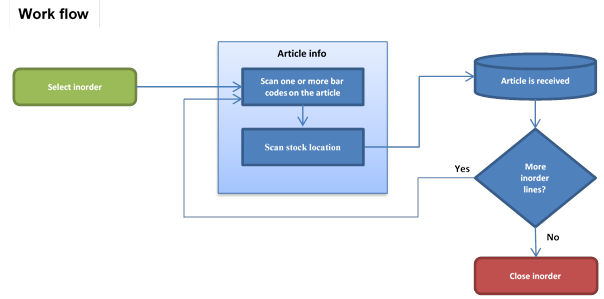

GS1/SSCC scanning

GS1 barcodes contains application identifiers, stating what information they contain. In this way, there is no need to define what information to be scanned, or in what order. When scanning a barcode, the information it contains will show on the screen. When you have scanned the barcodes you want to scan, set (select in a list or scan label) location to receive the article on that location.

Settings

Required information

It is possible to state the information that is mandatory for articles. If this information has not been entered when scanning the location label, a warning will be given, and the article will not be received.

You can select one or more of the following as mandatory information:

- SSCC

- Quantity

- Batch

- Weight

- Sub quantity

- Expiry date

- Production date

- Article comment

Group separator/stop characters

Different scanners use different characters as group separators. By default, * is used as a group separator. If your scanner is using another character, you can either change the settings of your scanner or we can change the group separator in Ongoing.

Application identifier

Ongoing WMS supports most application identifiers in GS1. If you use a special application identifier it can be included. For information about GS1 application identifiers see https://www.gs1-128.info/application-identifiers/.