Integration between Ongoing WMS and Autostore

Table of contents

Introduction

AutoStore offers automated storage and retrieval system (ASRS) that makes warehouses both space and time efficient. Learn more about AutoStore's automation systems by watching this video.

Connecting Ongoing WMS and AutoStore enables efficiency throughout the entire warehouse, not only through the automation. By integrating with our WMS instead of a standard ERP, you’ll be able to speed up and optimise your picking process by seamlessly combining picking both inside and outside the AutoStore. Book transportation and print shipping labels with our automated processes, and handle purchase orders and inbound deliveries with ease. Another benefit of connecting your AutoStore to Ongoing WMS is the use of our Automation API which creates a flexible but cost-efficient implementation.

Integrations

Ongoing WMS is used in several AutoStore projects together with our two partners Kardex and Element Logic who are both suppliers of AutoStore hardware and software solutions.

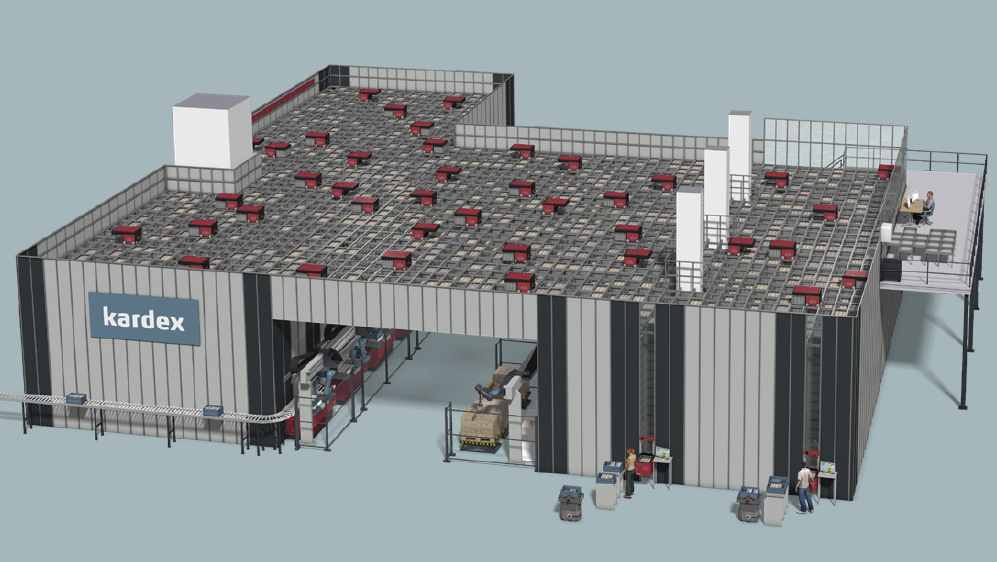

Integration by Kardex

One of the AutoStore integration between Ongoing WMS and AutoStore is provided by Kardex. Kardex is a global industry partner for intralogistics solutions and a leading supplier of automated storage solutions and material handling systems.

As a global AutoStore partner, Kardex offers a modular and flexible automated storage and retrieval system (ASRS) to process orders quickly and efficiently. Each AutoStore is designed based on their customers operational needs and is fully validated through their simulation software.

Contact Kardex if you want to know more about their integration of AutoStore automation solutions in Ongoing WMS.

Integration by Element Logic

The integration between Ongoing WMS and AutoStore is provided by Element Logic, who are specialized on AutoStore automation systems.

Contact Element Logic if you want to know more about the integration of AutoStore automation solutions in Ongoing WMS.

Companies using Element Logic integration

Some of the companies using Element Logics integration between Autostore and Ongoing WMS:

Integration basics

Using AutoStore warehouse automation with Ongoing WMS is straight forward and easy. The storage logic inside an AutoStore warehouse is mainly handled by a AutoStore supplier software application which integrates with Ongoing WMS. The aim of the software is to control AutoStore and communicate with the WMS.

Workflow

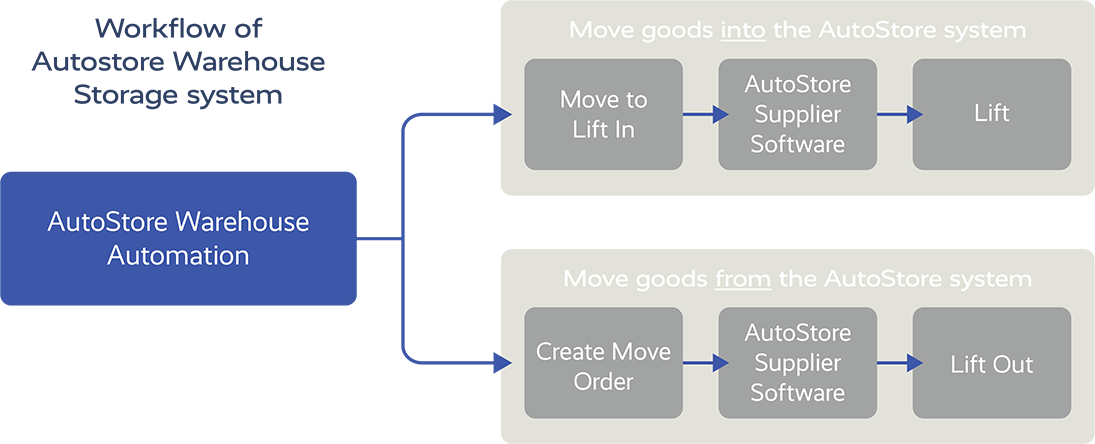

The workflow of an AutoStore warehouse automation system may be divided into putting away and picking up goods. From Ongoing WMS' point of view, the AutoStore system can be seen as a lift automation system. The lift is in the basic configuration represented by three warehouse locations, Lift, Lift_In and Lift_Out. Lift is the storage location of the goods whereas Lift_In and Lift_Out are used for putting away and picking up the goods.

The workflow can be illustrated as follows:

Putaway to AutoStore

To store goods in the AutoStore warehouse automation system:

- Move the goods to the input area of the system (Lift_In). Do this physically and in Ongoing WMS.

- Doing this will notify the AutoStore supplier software to move the lift (or conveyor belt) and store the goods.

- When the lift is done putting the goods away, it communicates with Ongoing WMS and moves the goods to the Lift's storage location.

Pick from AutoStore

To pick up goods from the AutoStore warehouse automation system:

- Create an order in Ongoing WMS.

- When the order is allocated, Ongoing WMS creates a move order that is sent to the lift.

- Complete the move order in the AutoStore supplier software.

- The lift then picks the desired items and moves them from the locations Lift to Lift_Out.

- The items should now be ready for picking.

For further technical details and more processes, go to our Developer pages.