Integration between Ongoing WMS and Blue Robot

Table of contents

Introduction

Blue Robot is a cube based state-of-the-art automated storage and retrieval system (ASRS) for small and medium sized businesses. Installations range from 1.000 bins up to 15.000 bins.

The cube can be installed in existing warehouses and does not require anything except from a leveled floor, power, and internet to be installed.

Blue Robot integrate with the Ongoing Automation API to retrieve Articles and Orders, and to return the result of the picking process.

Workflow

Working with Blue Robot together with Ongoing WMS will be an addition to your existing workflow, not a replacement. The only processes that change are those directly linked to picking from and loading goods into the cube.

Loading Goods

Blue Robot supports two processes for loading goods:

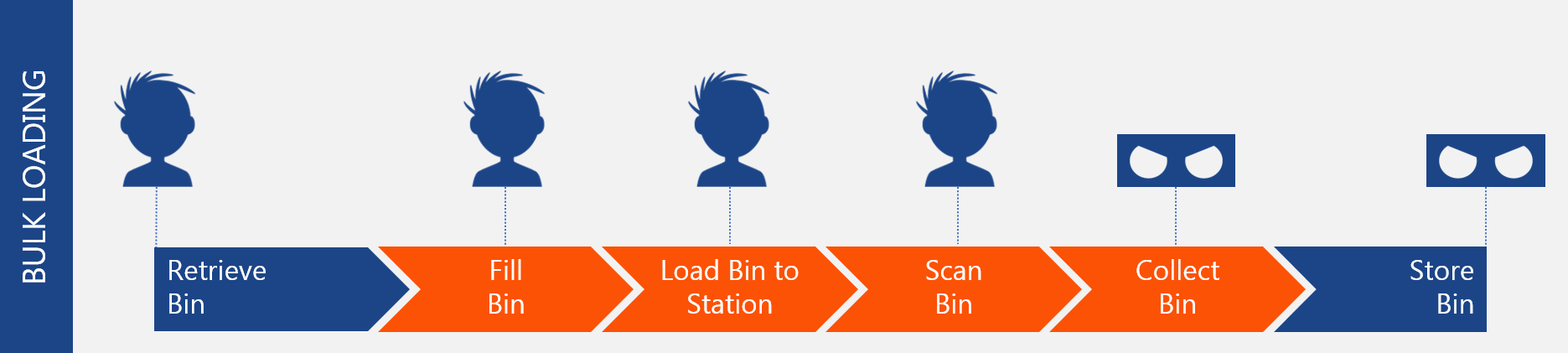

1. Bulk loading

The bulk loading process starts with picking up bins from a designated area, where the Blue Robot has placed empty bins available for human operators. The bins use standard form factors, which means that they will fit on standard pallets and pallet movers.

This enables a put away process where goods are put into their location or bin outside the robot. When the bins are filled with goods, the bins are transported to a station, scanned and sent back into the cube using the conveyors and the gantry moving robot.

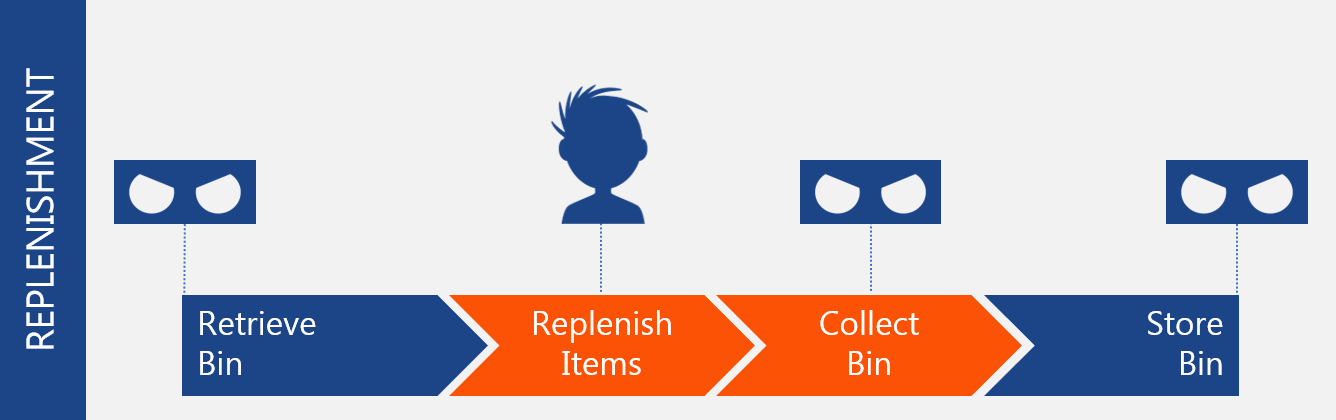

2. Replenishment

The replenishment process gives the operator the opportunity to refill bins running low of items. Blue Robot will deliver the relevant bins via the conveyor for the Operator to fill with goods needed.

This replenishment process can run in parallel with the picking process to refill bins to keep the picking process running.

Picking Goods

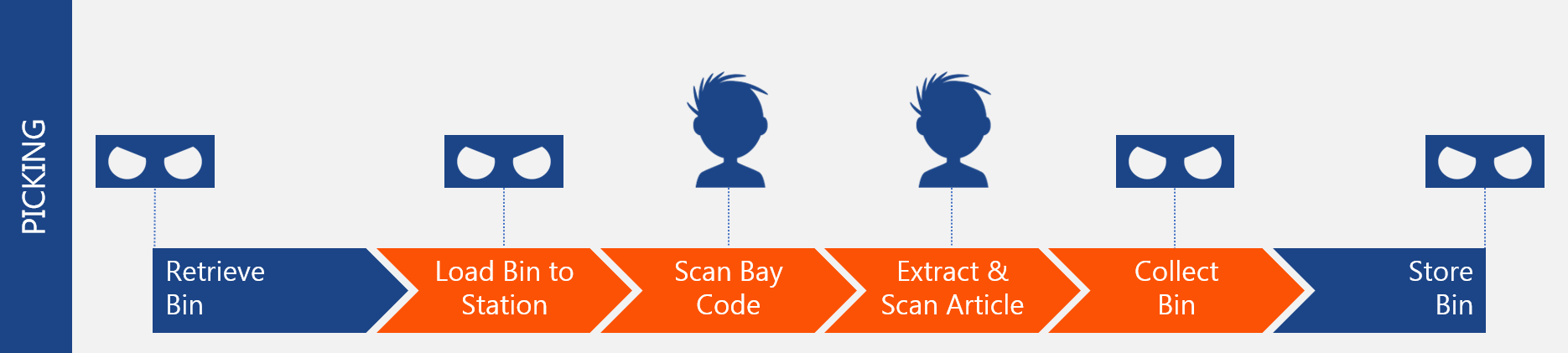

Blue Robot continuously fetches relevant information for picking from Ongoing via the integration. Picking batches are then created either as a continuous flow or manually, controlled by the operator, based on a configurable number of orders per picking batch.

Bins with goods are presented to the picker and the amount to be picked to each packing box is clearly shown. The picker takes items from the bin and places them in the correct box for packing.

The picker confirms every action by using a ring scanner, rather than clicking on the tablet. This saves time for every pick while always ensuring that the picker has two hands available for handling goods.

Once all order lines are picked from the bin, the bin is automatically returned to the cube and another bin is presented to the picker.

Contact Blue Robot if you want to get started or know more about the integration: jan-erik@bluerobotcompany.com.