Integration between Ongoing WMS and E-motions

Introduction

E-motions offers an automation solution for logistics heavy companies. Read more about how e-motions integrates to Ongoing WMS here.

Conveyor belt with weighing, dimensioning and scanning

E-motions has a solution which moves packages from one location to another via a conveyor belt. For example, you may want all your packages going to Sweden to arrive at one location and all our packages going to Norway arrive at another location where the packages are ready for transportation. The integration between Ongoing WMS and E-motions allows for these types of package movements to flow automatically. The integration works both when outsourcing to 3PL and when or handling your own warehouse.

Workflow

E-motions conveyor system together with Ongoing WMS works as follows:

- The order is picked and packed in Ongoing WMS and sent to shipping platform. The package is then placed on the roller belt.

- The package is scanned in E-motions conveyor system where the package is measured and weighted.

- The values are sent to Ongoing WMS Automation API.

- Information about the consignee's name, address, zip code, city, etc. is received from Ongoing WMS Automation API which allows the conveyor to automatically forward the package to the correct destination.

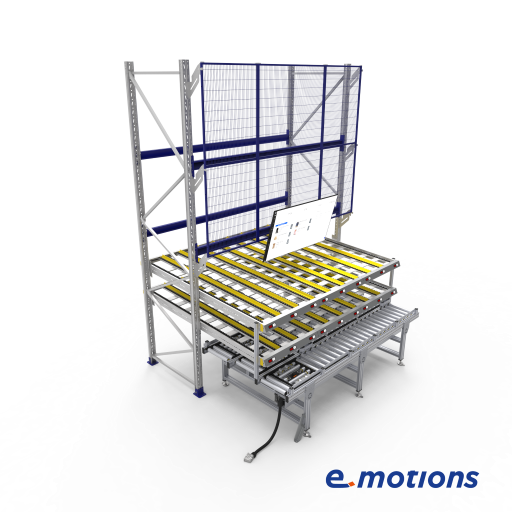

Pick-to-light

In a pick-to-light setup (also known as pick-by-light), the locations which the warehouse operator is supposed to pick from are indicated by lights. The warehouse operator selects an order to pick, and each bin from which he is supposed to pick lights up. As the operator picks items, he confirms each pick by pressing a button.

Their pick-to-light system is integrated with Ongoing WMS. E-motions reads which articles are supposed to be picked and reports back to Ongoing WMS when the warehouse operator confirms that the articles have been picked.

Click here to read more about E-motions pick-to-light solution.

Companies using this integration

Some of the companies using the integration between e-motions automation solutions and Ongoing WMS: