Integration between Ongoing WMS and SSI Schäfer LOGIMAT vertical storage lift

Table of contents

Introduction

SSI Schäfer LOGIMAT vertical lift module for small parts storage combines efficient picking with a space-saving design. It is possible to let the vertical storage lift pick orders in Ongoing WMS by integrating with the control system of the LOGIMAT vertical storage lift. In this integration, SharkWMS is used to manage the workflow between Ongoing WMS and the LOGIMAT vertical storage lift.

SharkWMS is a system used to control vertical storage lifts, such as SSI Schäfer LOGIMAT, and other types of automation hardware. It is capable of handling deliveries, transfers, refills and more. The integration between SharkWMS and Ongoing WMS to control SSI Schäfer LOGIMAT is developed and delivered by the Norwegian company Lager og Industrisystemer.

Also see this page for information on examples of automation hardware and how it may be used together with Ongoing WMS.

Workflow

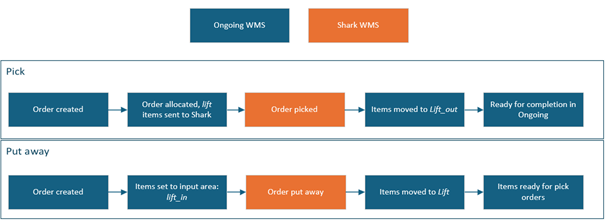

The automated storage workflow may be divided into putaway and picking goods. The storage hardware is in the basic configuration represented by three warehouse locations, Lift, Lift_In and Lift_Out. Lift is the storage location of the goods whereas Lift_In and Lift_Out are used for putting away and picking up the goods.

The workflow can be illustrated as:

Putaway to lift

To put away goods to the lift:

- Move the goods to the input area of the Lift_In in Ongoing WMS. Physically, the goods can be placed on a trolley with marked positions.

- Move on to a PC with the SharkWMS client and start the putaway process.

-

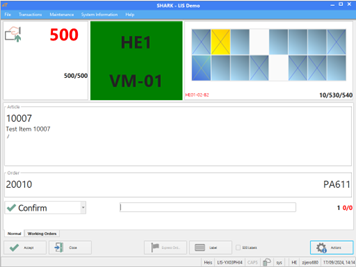

The trolley is then started on the LOGIMAT lift, and SharkWMS will now display:

- What position to take goods from on the trolley.

- What location to put the goods to in lift.

-

Item information.

Pick from lift

To pick goods from the lift:

- Create an order in Ongoing WMS.

- When the order is allocated, Ongoing WMS creates a move order. This order information is sent to SharkWMS.

-

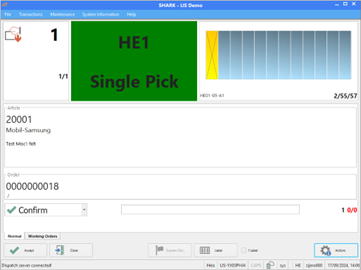

Complete the pick of the order in the SharkWMS application.

-

The pick job can be done as single picks or as a batch job with multiple orders across goods owners.

-

The pick job can be done as single picks or as a batch job with multiple orders across goods owners.

- The integration then picks the desired items and moves them from the locations Lift to Lift_Out when the pick is completed in SharkWMS.

- The items should now be ready to be picked in Ongoing WMS from the location: Lift_Out.

Getting started

Please contact Lager og Industrisystemer if you are interested in setting up this integration. They are a reseller of both SharkWMS and SSI Schäfer LOGIMAT vertical lifts.

Companies using this integration

The following companies are using the integration built by Lager og Industrisystemer: