Control of goods

Table of contents

- Introduction

- Activate the Goods operations module

- Create goods operations manually

- Create goods operations automatically when recieving goods

- Execute a goods operation order

- Next step

Introduction

Sometimes you need to have a process at the warehouse to check the goods in the warehouse for defects or quality before it can be sold or used in production. This can be set up in your Ongoing WMS by using what we call Goods Operations. In goods operations you create goods operation orders that define the article items that should be controlled in some way and in which goods status they should be set to when an order is executed.

Activate the Goods operations module

The Goods operations module in the Warehouse top menu is not visible for all users by default. If you cannot see the module, please follow these steps.

-

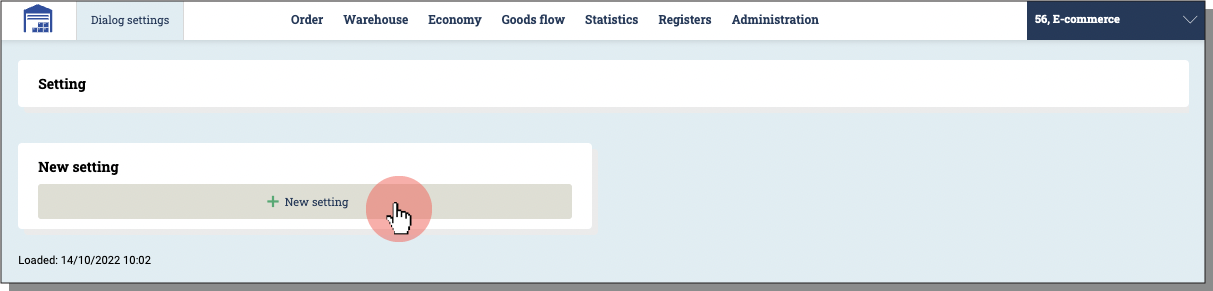

Go to Administration => System settings => New setting.

-

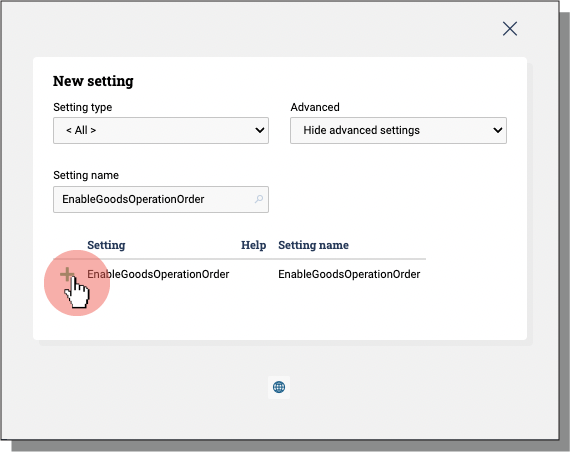

Locate EnableGoodsOperationOrder and click the green plus sign to add the setting.

-

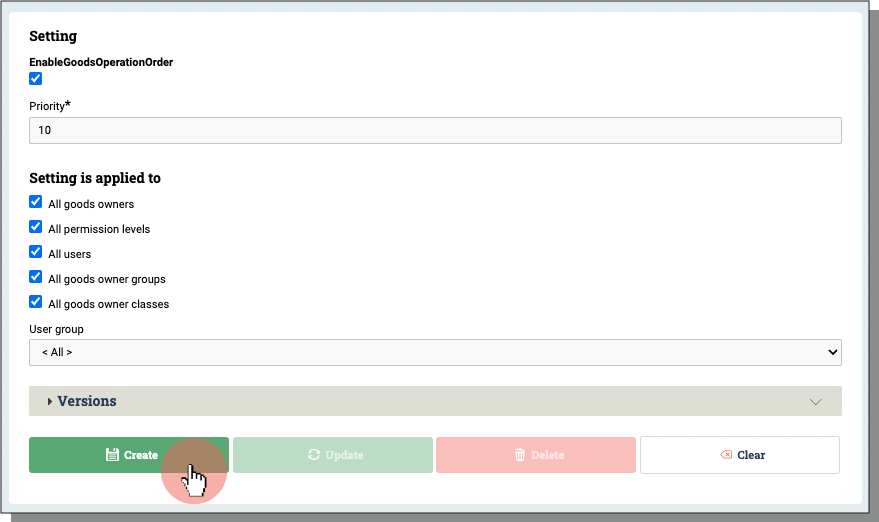

Select the setting by ticking the box underneath the name of the setting. Set priority to 10. Pick the users to whom the new setting should apply to. Click Create.

-

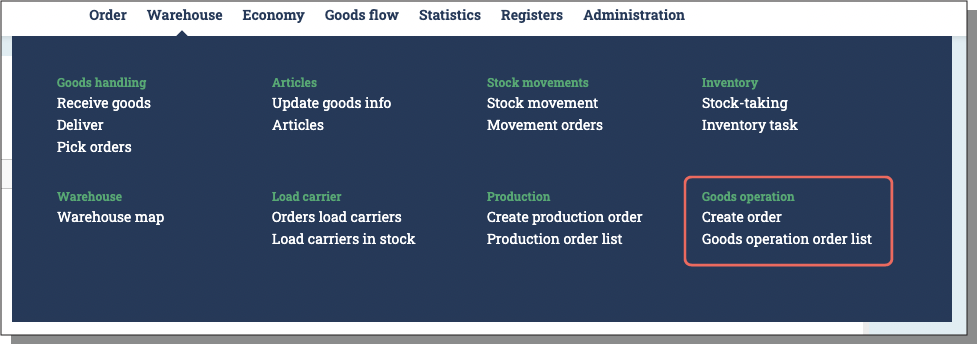

The Goods Operation module should now be visible in the Warehouse top menu

Create goods operations manually

-

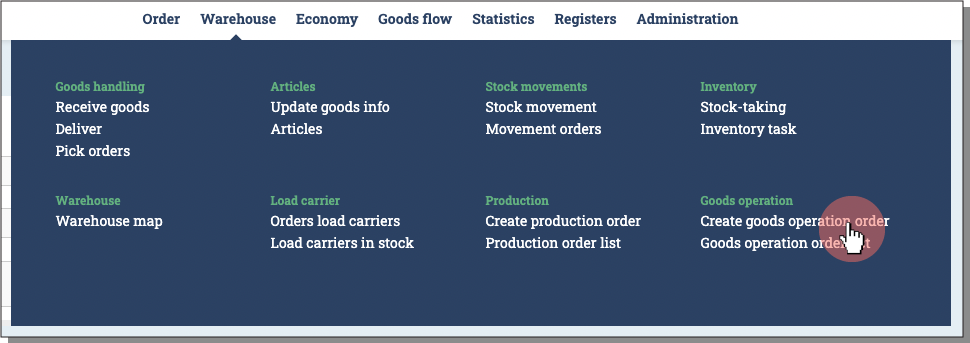

In order to create goods operation orders manually, go to the top menu Warehouse and select Create goods operation order in the Goods operation module.

-

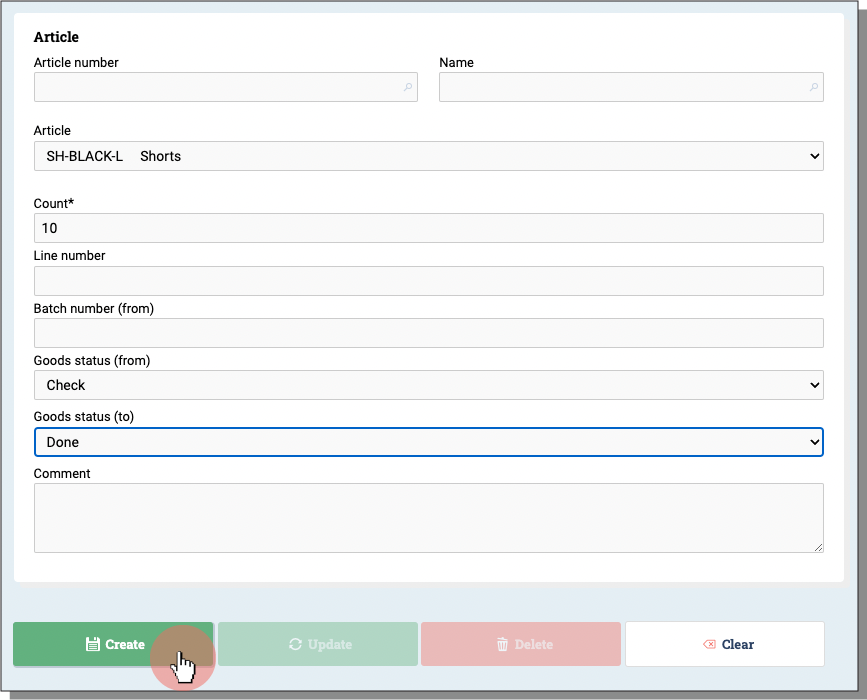

Supply an order number and other order information. Choose the articles that should be a part of the goods operation order and their count. Here, you also supply the goods statuses that the goods should be in to be on the order (from status) and the goods status they should change to when the order is executed (to status). If you do not know how to create statuses and how to assign them to your articles, please follow step 3.

-

If you do not know how to create statuses and/or assign a status to articles, follow these steps. Otherwise, move on to step 4.

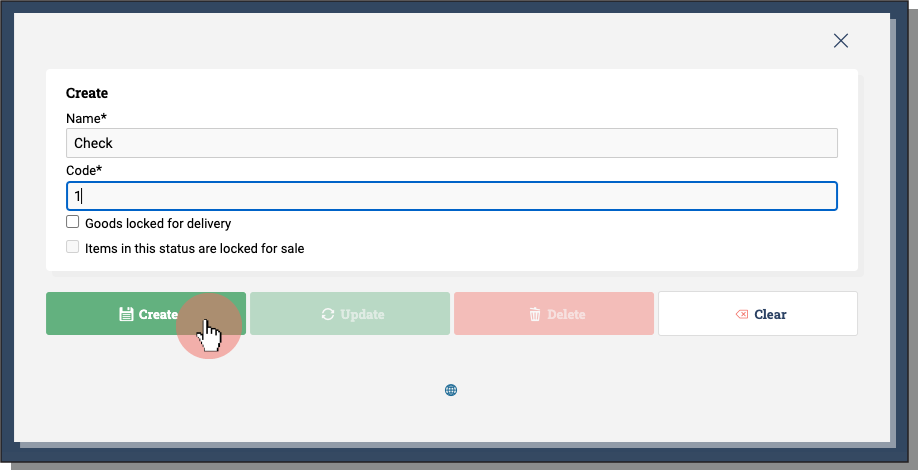

The goods statuses are created in the top menu Registers in the Articles module. Here, you can add attributes to the different statuses such as if the goods that are received in the given status should be locked for delivery, or locked for sale.

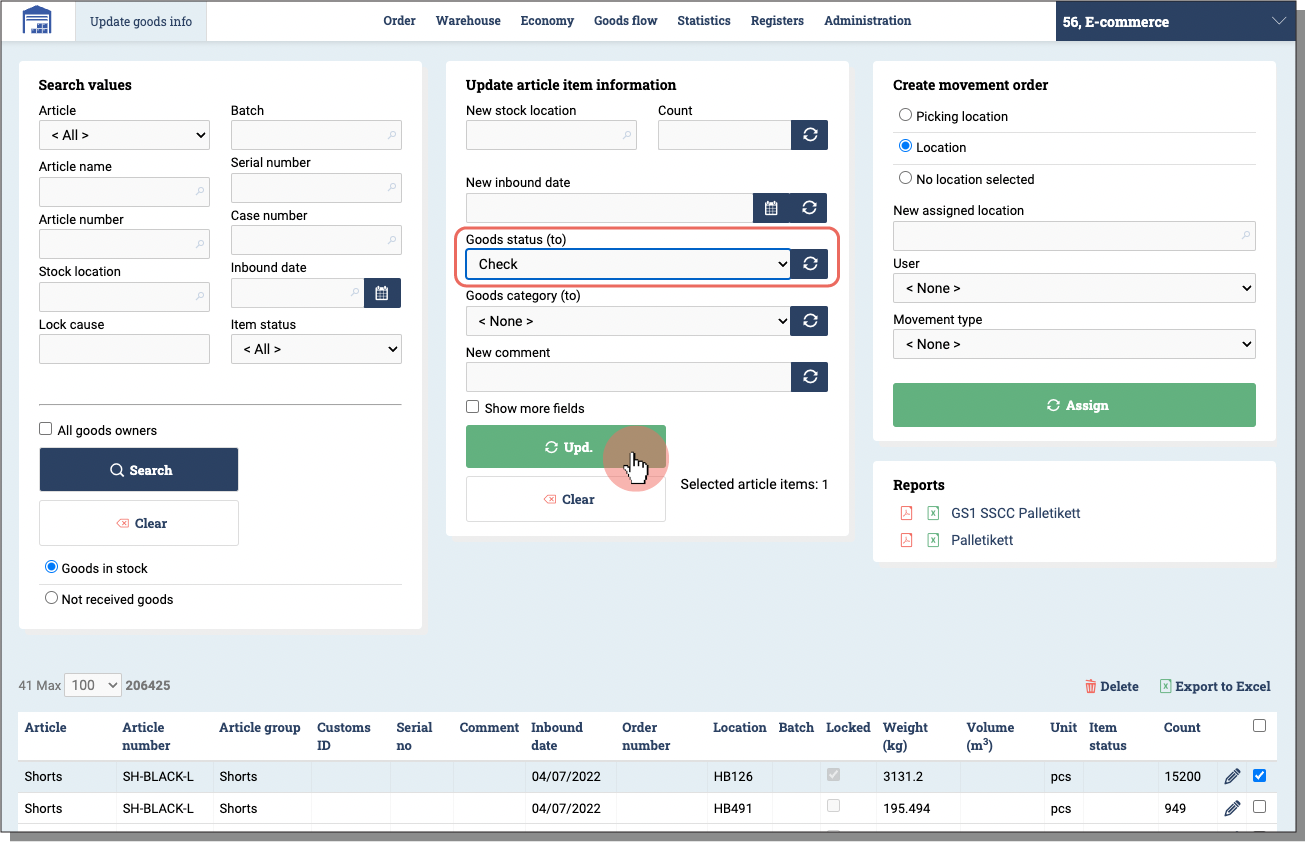

To assign a status to the articles, go to the top menu Warehouse and select Update goods info under the articles module. Select the articles and assign them a new status. Click Update.

-

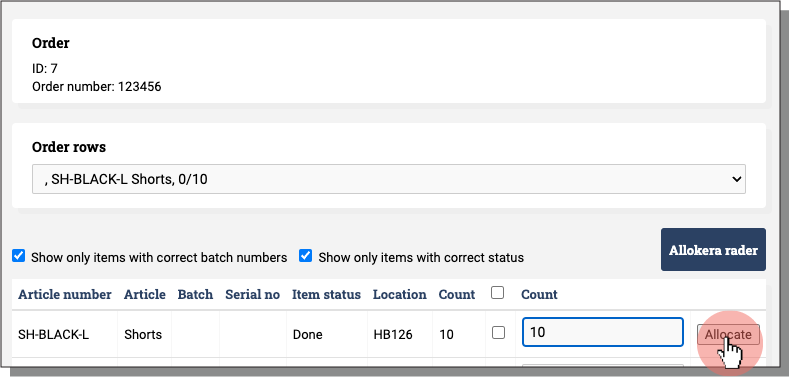

When the order rows are created, go to the top menu Warehouse select Goods operation order list in the Goods operation module. You can now connect article items to the order by marking the order and press Allocate in the goods operation order list. Here you then choose the article items you want to be connected to the order, i.e. the specific items that are supposed to go through some warehouse specific process or control.

Create goods operations when recieving goods

When you recieve goods, the same funtionallity as above could be achieved automatically when pressing the Recieve-button. Then a goods operation order with the article items that you have just received is created. The status of the received articles is also set automatically to the from status in the order.

Execute a goods operation order

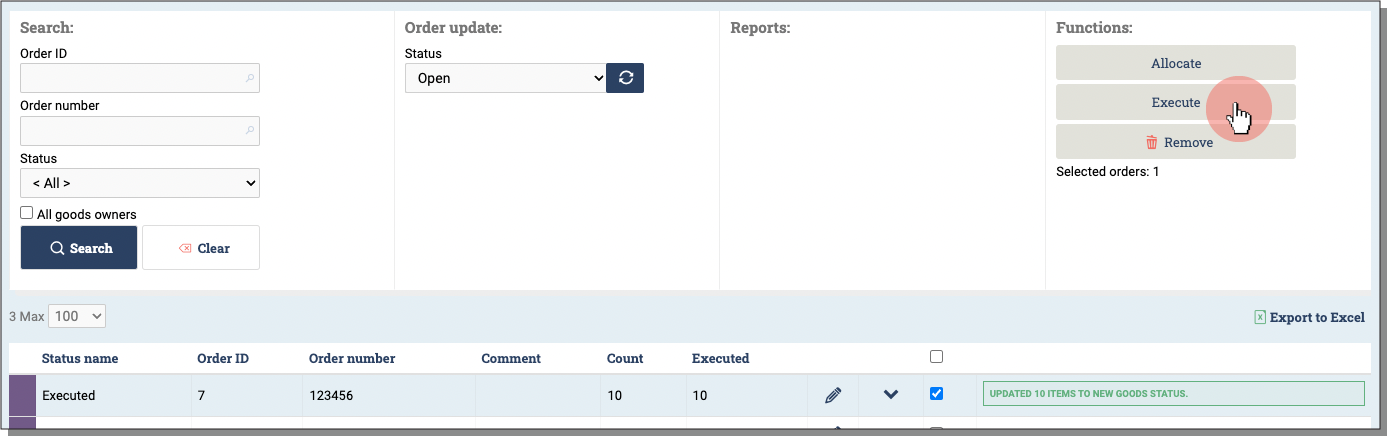

To execute a goods operation you mark the order you want to excecute and press Execute. Then the article items on the order will change status to the status you selected as Goods status (to).

Next step

To activate this in your Ongoing WMS, some settings and adjustments need to be applied by your contact at Ongoing. Please contact us to discuss your setup to get a more efficient process for quality control.