Cross-docking scanning

Table of contents

Introduction

The cross-docking inbound scanning is used when dealing with cross-docking or e.g. running large campaigns where there are already orders waiting for the arriving goods. You will pick the orders directly as you receive the goods. The orders that are not completed will be placed in dedicated sorting locations to wait for the remaining goods.

Preparations

Setting up an aisle

We recommend to use a dedicated space in your warehouse for sorting the goods on the orders. This can be e.g. a shelf with boxes or separate floor areas depending on the characteristics of the goods. In Ongoing WMS you should setup the sorting locations like a regular aisle, tentatively with a suitable location type. Learn how to set up an aisle here. Each sorting location should be labelled with a barcode containing its name.

Functions that are run when closing an order

When you close an order different functions might be run, e.g. changing the order status or sending the order to a shipping platform and print the labels. What will happen upon closing an order depends on your system configuration. Talk to your contact person at Ongoing to adjust the setting.

Orders

Orders must be in status with a status number lower than 320 to be suggested in the scanning. If you want to change which order statuses that will be suggested, talk to your contact person at Ongoing.

Scanning process

This feature can be used with or without a purchase order. If you are not using purchase orders, you will start on step 2 directly.

- Select what purchase order (inorder) to receive on.

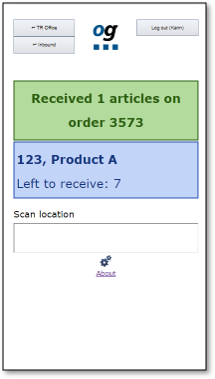

- Scan the barcode of the first article and type in how many you have received.

-

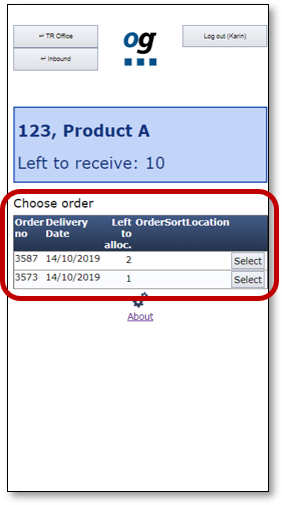

All orders waiting for this article will be shown in a list. Select an order to pick the item(s) on the order.

-

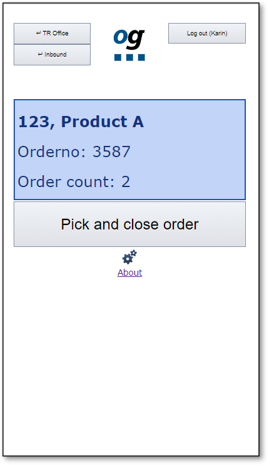

Pick the orders

-

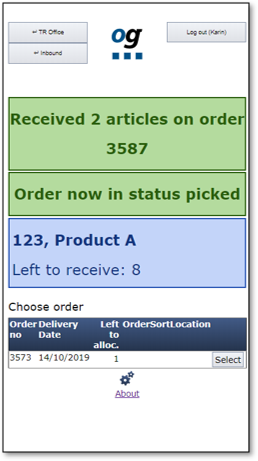

a. If this was the last (or only) item on the order the functions configured to run upon closing an order will be executed.

-

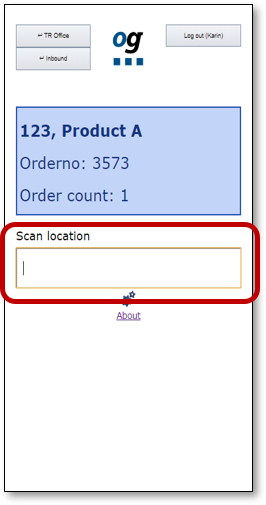

b. If the order is not completely picked you should place the item(s) in any free sorting Location.

Confirm by scanning the barcode on the sorting location where you place the item(s). This location will now be set on the order, and it is possible to display the sorting locations in the order list.

-

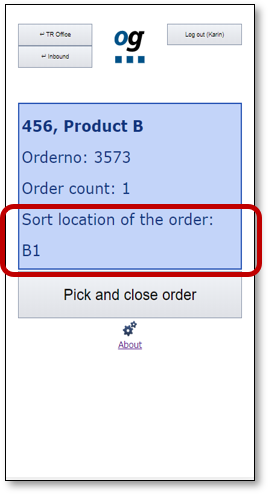

c. If the order has already been dedicated to a sorting location the scanner will tell you in which sorting location to place the item(s) in.

-

a. If this was the last (or only) item on the order the functions configured to run upon closing an order will be executed.

-

If all items received were not picked on orders, you can store the rest of the items in any warehouse location by scanning the barcode.

Location suggestions can be activated to guide you where to store the goods.