Integration between Ongoing WMS and Kardex

Table of contents

Introduction

Kardex offers automation hardware, such as vertical lift modules and AutoStore solutions. They are also developing and maintaining integrations between Ongoing WMS and their automation software. The integrations are capable of handling deliveries, transfers, refills and more.

Learn more about automated picking using Kardex' vertical lifts modules in this YouTube video. You can also find more information about their AutoStore integration on the AutoStore integration page. Contact Kardex if you want to know more about the integrations or their automation solutions.

See this page for more information and examples of automation hardware and how it may be used.

Workflow

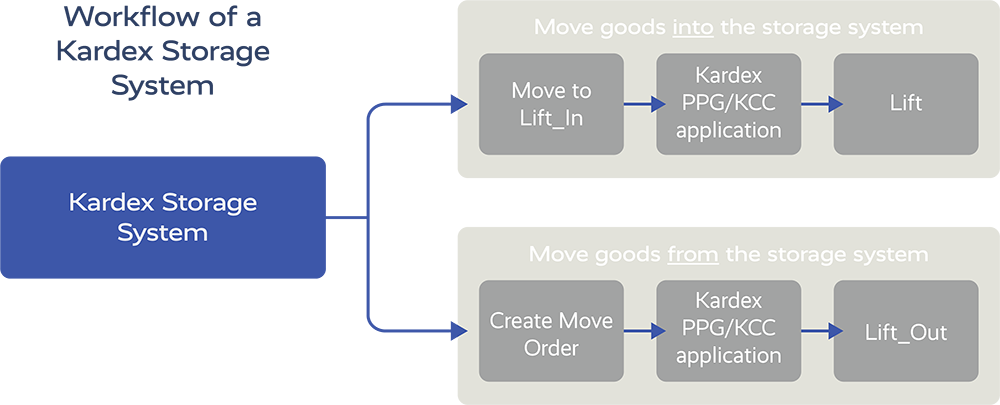

Using Kardex storage automation with Ongoing WMS is straight forward and easy. The workflow for their vertical lift modules and AutoStore solutions follow the same principle. The storage logic inside Kardex' automation hardware is mainly handled by their automation software applications which integrate with Ongoing WMS. For their vertical lift modules, the application is called Power Pick Global (PPG). For their AutoStore solutions, the application is called Kardex Control Center (KCC).

The automated storage workflow may be divided into putting away and picking up goods. The storage hardware is in the basic configuration represented by three warehouse locations, Lift, Lift_In and Lift_Out. Lift is the storage location of the goods whereas Lift_In and Lift_Out are used for putting away and picking up the goods.

The workflow can be illustrated as follows:

Putaway To Lift

To putaway goods to the storage:

- Move the goods to the input area of the lift/AutoStore (Lift_In). Do this physically and in Ongoing WMS.

- Doing this will notify PPG/KCC to move and store the goods

- When the lift/AutoStore is done putting the goods away, it communicates with Ongoing WMS and moves the goods to the storage location.

Pick From Lift

To pick up goods from the storage:

- Create an order in Ongoing WMS.

- When the order is allocated, Ongoing WMS creates a move order that is sent to the lift/AutoStore.

- Complete the move order in the PPG/KCC application.

- The lift then picks the desired items and moves them from the locations Lift to Lift_Out.

- The items should now be ready for picking.

Companies using this integration

Some of the companies using the integration between Kardex automation equipment and Ongoing WMS: